The floor pans are the most important part of your car. They support the body and keep the water out. When I got my car there were holes under the battery and near the front on both sides. I once I got the old ones out I welded new ones in.

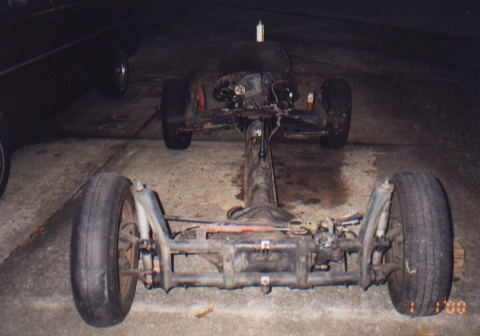

I found that the easiest way to get the old ones out is to

take the body off and then use a saws-all to cut the majority of it off.

I then used an air chisel to get the rest of it off of the chassis.

After I did this I then sand blasted the area and ground it down where I was going to weld the new ones on.

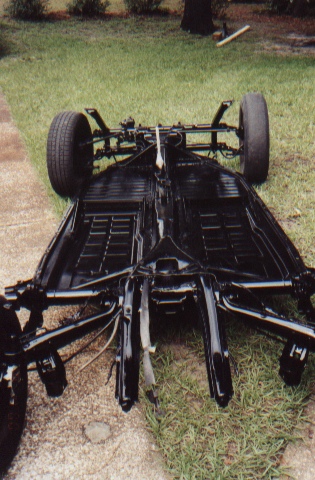

Since I couldn't spot weld them in, I just tack welded them in.

Once I got the new floor pans in I sand blasted the whole chassis and painted it all black. I eventually got a few good coats on.

Another thing that I did is to put some type of undercoating on the pans. What I used isn't exactly undercoating but it works. The stuff I used is called Vulkem. It is used as a moisture barrier on concrete block walls in buildings. It is black and very messy. Once it dries though it is rubbery, waterproof, fireproof, and has no smell. This stuff is awsome.

I have now put the body to pan seals on. They went on easy. I put some caulking on the bottom of them to hold them in place while putting the body on and to keep even more stuff out of the car. I will probably put some on the top to help seal it even more.