The body work that I have done has gone from big to little. This includes welding new door pillars in (which both door fit on and shut good), to fiber glassing the spare tire wheel well.

Door Pillar Repair

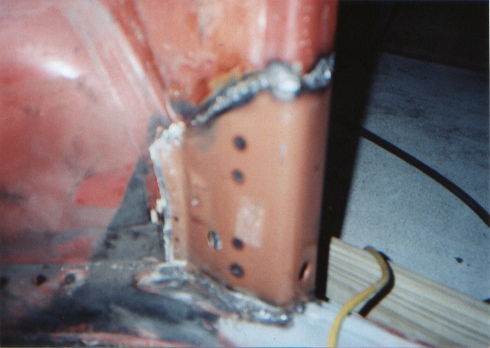

The hard part of welding the new door pillars in was getting them to fit almost perfect before you welded them in. After we got them to fit in relatively well and spot welded them in, then it went very well from there on out. Here is a picture of the cut out part. (This is just the left we did this on both sides though.)

In these pictures I have welded in the new A-pillars. First we cut some out roughly using a saws-all. Then we used the new pieces to make a line where we are going to cut. To do the good cutting I think that we used a jigsaw or a die grinder. On the first one we cut it out exactly so we were doing a butt weld. This was not very easy.

In this left picture we are welding on a new panel where it was rusted out. This was a lot easier than the A-pillar job. We left some overlap and welded on that.

In this picture we are grinding on the A-pillar to get the new one to fit just right. The picture on the right is of the new A-pillar welded in. For this one we left some excess to weld onto. Then we cleaned it off to make a good weld and then fitted the new pillar on to it. This was a lot easier to do and make look good. The door also fits great. Before we welded it on for good we tacked it on to see how the door would fit.

Spare Tire Well Fix

The fiberglass stuff is very neat stuff. You mix the two parts together, soak the cloth in the stuff and put it where you want it and it dries very hard.

I also had to replace the old rear apron. The old one was held on by about five welds so it was easy to get off. The new one fit the bug but the track that the rubber seal goes in was about 3/4 of an inch to low. We drilled the seven or eight spot welds out and moved it up to where it was supposed to be. We welded the apron in place and it looks good. This one won't come off like the last one did. I'll have pictures soon.

I have also had to fix a few dents in the doors, hood, and near the fenders. This went good but I will have to re-primer those spots with good primer. This won't take long because they are small spots. I might have pictures on here soon.

Door order

When I put the doors together it went very well and was not complicated. The only thing that you have to do is to be very careful. The order that I put it together is:

Door seal around the edge

Door stopper

Latch on inside of the door

Felt holder thing at bottom back of door

Outside window scraper

Inside window scraper

Clips for the felt track

Felt track

Vent window

Glass

Regulator

Handles and other stuff

You need to be careful with the rubber on the scrapers when you are putting the vent windows in. Or else it might pull it away from the scrapers, you might want to spray some lubricant on it. Just be real real careful when you are doing this.